Big Data techniques have taken all aspects of life by storm in the last few years. Be it the Medical profession, stock markets, oil exploration, and everything, these techniques are providing incredible insights by catching ‘signals’ embedded in ‘noise.’ However, many of these methods have not penetrated into Industry 4.0 primarily because of the conservative nature of this business. Now, enough research has been done in academia and the AI firms for Industry 4.0 applications that the early adopters are going to enjoy an unprecedented advantage, maybe even overturning the established players. Just a few years down the line motors and machine tools industry will look very different -both in terms of players and the tools they deploy to give themselves an ‘unfair advantage’.

The pump and motors typically face issues like electrical unbalance due to an Uneven Air gap from badly worn sleeve bearing. Then there are problems due to misalignment which causes noise and leads to unbalance in the power circuit. Also, there could be electrical unbalance due to uneven magnetic attraction between stator and rotor which causes the shaft to deflect results in mechanical unbalance. All these events cause a faint harmonic signal on the electrical source. The AI Engine can be trained to recognize these signals using supervised learning techniques.

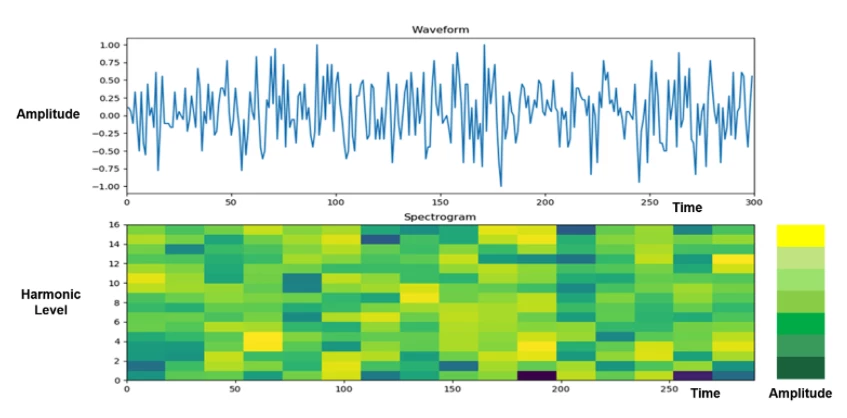

Traditional AI methods like Logistic Regression can be enhanced with other suitable techniques like Convolutional Neural Net or ensemble methods like Random Forest. The picture below shows how to pre-process the current amplitude data and apply STFT based approach for recognizing a slight imbalance in a rotor shaft. The spectrograms can be fed into the same image recognition algorithms which can figure out, for instance, whether you are happy or sad.

Just being able to monitor harmonic distortion is an advantage in itself. For instance, in the case of air compressors higher THD (Total Harmonic Distortion) content can indicate an efficiency decrease due to the heat loss. While THD itself can serve as a metric, some of the unsupervised learning techniques can predict how much time it would take to reach that metric if the measurement is being done on a 24x7 basis.

This type of methodology when applied at a plant level is even more important and shows the overall health of the factory at a coarse level such as maintaining the Power factor of the plant by understanding the load patterns and prompting the user to take an anticipatory action or monitoring the Maximum Demand continuously and prompt the user to change the load patterns which reduces the penalty in billing.

For a Big Data-based system, there are two key aspects that often get overlooked. One is that of interaction with the system. That allows one to get you an actionable inference without having to be a Math Ph.D. and a Senior Software engineer. This can be achieved by using a Natural Language Processing (NLP) based interface into the monitoring system.

The second important aspect is a standard API interface to get the data into an excel sheet or using Python or any other language of choice. Most power monitoring lock you into their interface and do not provide a standard API to get to your own data without having knowledge of SQL.

In summary, Big Data and Machine Learning is set to revolutionize Industry 4.0. However, there are some caveats. There needs to be emphasis on Edge Based AI to manage the cost and security of ‘Data in Flight.’ The data going into the AI Algorithms needs to be carefully curated since like all computer programs ‘Garbage In- Garbage Out’ holds for it as well.

Lastly, AI is not meant to replace the experts and engineers in the field, but rather to give them tools and insights so that they can make better decisions to reduce the cost of the operation, increase the uptime and generally maintain a more efficient operation. There is no substitute for intuition. In games like Go and Chess, AI can routinely beat the world champions but a human and AI together is unbeatable. AI can draw upon the knowledge of the human experts and that is what some of the techniques of Unsupervised learning bring to the table which can bring huge benefits in power management.

Lokesh Johri: He has past experience working in the Software and semiconductor industries and is currently leading an AI-IOT start-up based in Silicon Valley

Vinod Joshi: He has past experience in Instrumentation Product development and its marketing, currently a Marketing Director of AI-IOT Start-up www.Tantiv4.com

Know more about tools for power analytics and advanced AI solutions to manage power in industrial set-up visit MiDAS.